Significant trainings on the benefits of concrete blocks have been started to be provided to companies and employees by the leading organizations of the construction industry. The basis of these developments is the desire to expand the concrete constructions that are environmentally sensitive and minimize carbon emissions..

Concrete blocks can be produced both in different sizes and dimensions and using various materials. The benefits of concrete blocks are the ability to obtain structures that remain solid and well for many years using concrete blocks. However, some issues have significance to achieve this efficiency such as choosing a supplier, raw materials of the product and using these materials with the correct proportions, workers’ experience and competence in the construction phase.

The benefits of concrete blocks can basically be summarized under the following headings:

Concrete blocks have a high thermal insulation value because gaps are filled with appropriate materials. Recently, studies have been started to maximize the advantage of thermal insulation. In these studies, a system called U-value has been developed which is used to realize appropriate block and insulation combinations. U-value is used to measure the rate of heat transfer from one material to another.

Thanks to these studies for higher performance of concrete blocks, the minimum air permeability required by some warehouses can be provided.

The concrete block usually comes to mind with a traditional gray tone and a cool look. In fact, this is a matter of choice. Because the exterior of concrete blocks can be transformed into a stylish design with various patterns and surface coating.

The architectural structure and aesthetic features of a workplace can be important for potential customers. Or they may want the house they want to sit to have a nice look and the benefits of concrete house. Therefore, there are many options for both housing and businesses.

Due to natural mass and damping of concrete block, advanced sound insulation is provided on walls and floors. No additional costs are required to have sound insulation.

Especially for people living in apartment buildings, sound and noise insulation between apartments is a quite important issue. Its standards have been set by the building and environmental noise regulation. Attention should be paid to this issue at the initial construction stage and in the selection of materials. Sound insulation can be maximized in houses constructed using concrete blocks.

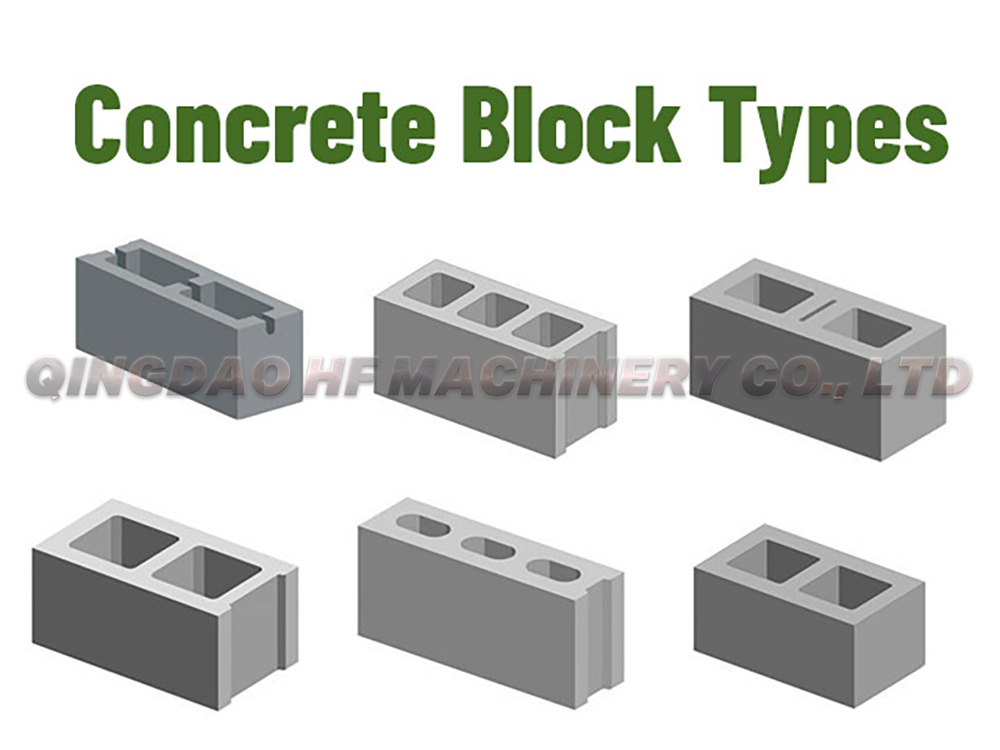

The fact that concrete blocks are able to have different designs is not only limited to external surface applications. From a structural point of view, it is remarkable that they can be produced in different sizes and dimensions.

GlobMac, which manufactures briquettes and concrete blocks for high-end projects and sells concrete block machines all over the world, can meet your high quality product needs for all your construction projects. Thanks to its superior technical service, it accompanies you after sales services as well.

Back To The List

Back To The List

The Molding Vibration Block Machine has a short forming cycle and high production output. The continuous increase in vibration frequency during material feeding and forming vibrations reduces the feeding time by 3 to 4 seconds. The table vibration machine

Brick manufacturing has been an essential part of construction for centuries, providing durable and aesthetically pleasing building materials. However, the process of producing bricks is not without its challenges. As the world becomes more environmentall

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.